Szymon Rewilak

AuthorPublished on October 20, 2025

Did you like this article? Share it!

Every manufacturing company has activities that do not add value to the product yet consume time, resources, and employee energy. In the book Toyota Production System: Beyond Large-Scale Production (1978), Taiichi Ohno identified seven of the most common types of waste.

In Lean Manufacturing philosophy, these activities are called Muda – meaning wastefulness or uselessness (Japanese: muda = useless, unnecessary).

Japanese companies, led by Toyota, have been effectively eliminating Muda for decades, achieving high production efficiency and flexibility. Understanding the seven classic wastes of Muda helps identify where productivity may be leaking in your company — and how to fix it.

1. Overproduction

Producing more products than the market actually needs or producing them too early. This often results from trying to maximize machine utilization, avoid downtime, or poor planning. It leads to excessive inventory, storage space usage, and frozen capital in unsold goods — along with risks of damage or obsolescence.

Example: A factory produces a large batch of components before receiving an order, leaving finished parts sitting in storage for weeks.

2. Waiting

Any situation where workers, machines, or materials remain idle because they cannot proceed with work. This can result from poor organization, missing materials, equipment failure, or communication delays. Even short, repeated waiting periods add up to a significant loss of productive time and affect workflow rhythm and motivation.

Example: A machine operator has to wait for semi-finished materials because the warehouse didn’t prepare the batch in time.

3. Unnecessary Transportation

Any needless movement of materials, components, or finished products between production stations, warehouses, or facilities. Excess transport adds no value, increases the risk of damage, creates chaos, and generates labor and energy costs. The root cause may be poor plant layout, lack of standardized flow, or weak internal logistics planning.

Example: Semi-finished products are transported multiple times between halls before reaching final assembly, adding several hours to the production cycle.

4. Overprocessing

Occurs when a production process includes steps not required by the customer or that do not increase product value — such as excessive polishing, redundant quality checks, or overly complex methods. Often caused by misunderstanding customer requirements or poorly designed procedures. It raises costs, prolongs lead times, and strains resources.

Example: A manufacturer polishes a metal surface to a mirror finish even though the client only requested a matte texture.

5. Unnecessary Motion

Refers to inefficient or needless actions performed by workers, such as walking to fetch tools, searching for documents, bending, reaching, or rotating parts. These actions often go unnoticed but waste significant time over a shift. They slow production, cause fatigue, and increase the risk of errors or accidents.

Example: An operator must leave their workstation each time to retrieve a measuring tool instead of having it within reach.

6. Excess Inventory

Keeping more materials, semi-finished goods, or finished products than necessary for current operations. While it may seem like protection against delays, it leads to wasted space, higher storage costs, and difficult stock management. Excess inventory often hides deeper problems like unstable supply chains or poor planning.

Example: A plant orders oversized batches of raw material that remain unused for months, tying up capital and warehouse space.

7. Defects

Waste resulting from rework or scrapping defective products. Every defect means extra labor, material waste, and lost time that could have produced good units. Defects typically arise from lack of standardization, poor quality control, or outdated process data — eroding customer trust and profitability.

Example: An operator uses an outdated assembly instruction, causing recurring defects across an entire batch.

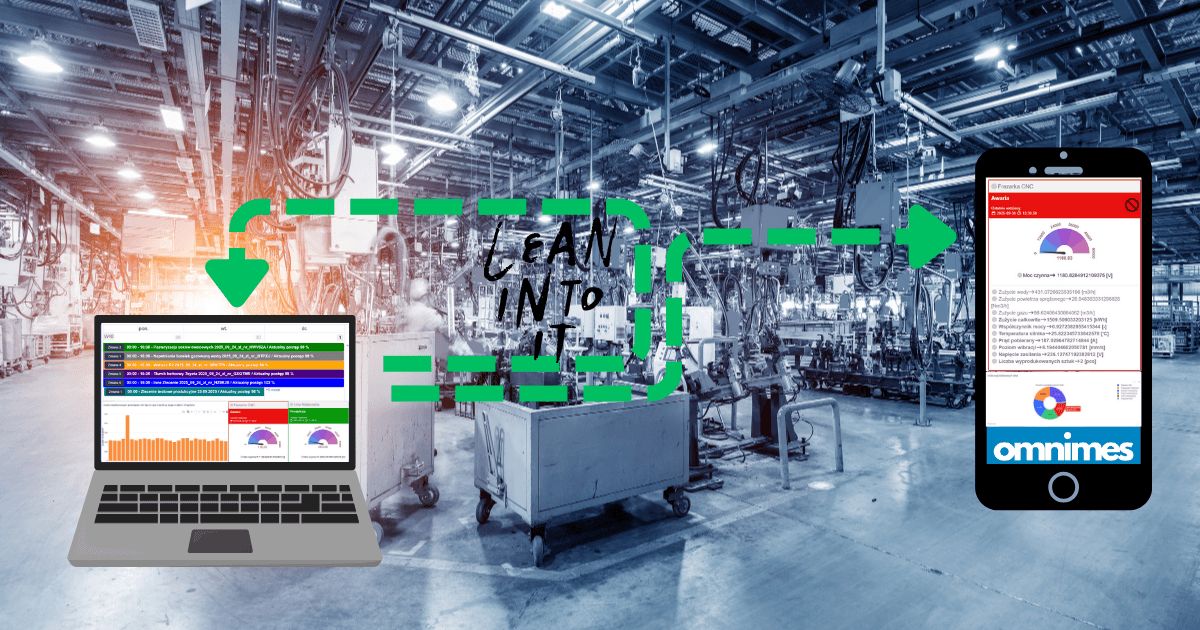

How a MES System Helps Eliminate Muda

Identifying and reducing Muda requires full process transparency and real-time data. A MES (Manufacturing Execution System) bridges planning and production, enabling precise monitoring of operations.

MES systems automatically collect data from machines and workstations, track production progress, analyze downtime, and identify bottlenecks. They also generate detailed OEE (Overall Equipment Effectiveness) reports, helping you understand how each type of waste affects overall plant performance.

By implementing a MES, a company gains real-time control and data-driven decision-making — a practical application of Lean philosophy in digital form.

Eliminate Waste with OmniMES

Every downtime, every case of overproduction, every data error means real financial loss. With OmniMES, you can not only detect them but also effectively reduce them — easily and without a long deployment process.

OmniMES stands out with fast installation and intuitive setup, allowing your factory to start working with a modern MES within just a few days.

Start producing more efficiently – schedule an OmniMES demo today.